MINI-LIFT HAS MANY USES

Mini-Lift Jobs Beyond Trees

Installing Signs

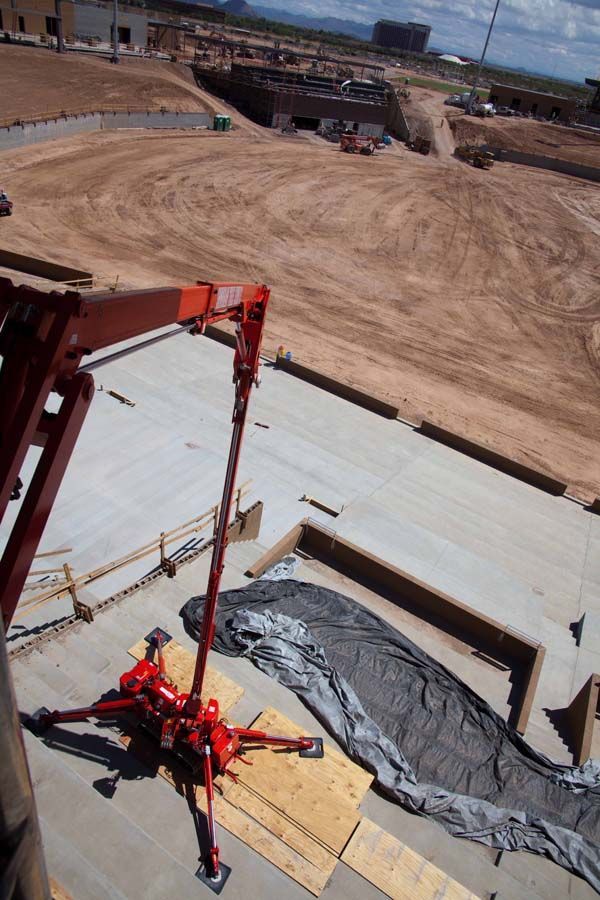

I’ve had a couple jobs with the lift this summer that did not involve trees! I wanted to share some pictures so you can see the possibilities and range of interesting things I get to do from time to time.

I was contacted by a church which had a large wooden cross on top of the building. The cross-beam had started to deteriorate and needed to be replaced. I was able to set up beside the church and reach up, over the cross. We loosened the cross-beam and slid it onto the rim of the basket, and I tied it. Then I took it down. Several weeks later, when the replacement beam was ready, I came back and took it up. We slid it into place and put in bolts to hold it. Here is a view from the top:

I was interested to see how this metal artist started the patination process. First, muriatic acid (pool acid) is sprayed on the bare metal. Then, hydrogen peroxide is sprayed on top. As soon as the hydrogen peroxide hits the surface it starts to rust. It will continue to develop a richer color and texture, but would probably never rust the metal away. On a side note – use a respirator and gloves if you ever think about doing this at home! I subsequently used this process on a project here at my home, which I am waiting to write about. It is really neat and I think you’ll like it!

There are two hatches that open for access to the inside of the sign to change bulbs. The electricians came next to hook up the electric and tuck in all the wires you can see outside the right side of the sign. The light comes out through the frosted Plexiglas and I think it looks good day or night!